Precision and Efficiency Unleashed: Exploring SMC Oil Tank Moulds

2023-10-17

Introduction

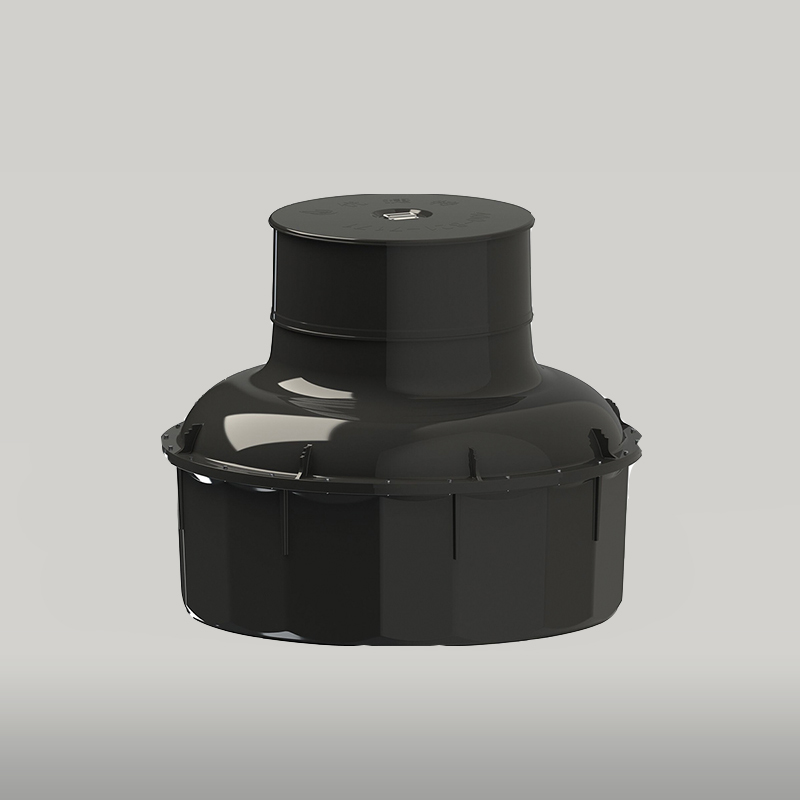

In industries such as automotive, aerospace, and manufacturing, the production of oil tanks demands precision, durability, and efficiency. SMC (Sheet Molding Compound) oil tank moulds have emerged as an indispensable tool for creating high-quality oil tanks. With their innovative design and advanced manufacturing processes, these moulds ensure the production of oil tanks that meet stringent standards and provide reliable performance. In this blog, we will delve into the features and benefits of SMC oil tank moulds and discover how they revolutionize the manufacturing of oil tanks.

1. Superior Strength and Durability

SMC oil tank moulds are specifically engineered to produce oil tanks with exceptional strength and durability. The SMC material used in the manufacturing process combines chopped glass fibers, thermosetting resins, and fillers. This unique composite material offers high tensile strength, impact resistance, and dimensional stability, making it ideal for oil tank applications. The resulting oil tanks exhibit excellent structural integrity, allowing them to withstand demanding operating conditions, such as extreme temperatures and pressure variations.

2. Lightweight Design

One notable advantage of SMC oil tank moulds is their ability to produce lightweight oil tanks without compromising strength or durability. The SMC material has a high strength-to-weight ratio, making it an ideal choice for industries seeking to reduce the overall weight of their products. Lightweight oil tanks contribute to fuel efficiency in automotive applications, increase payload capacity in aerospace, and simplify handling and installation in various industries. SMC oil tank moulds enable the production of lightweight tanks that offer performance benefits across multiple sectors.

3. Complex Shapes and Customization

SMC oil tank moulds excel in producing oil tanks with complex shapes and intricate designs. The moulding process allows for precise replication of intricate details and geometries, enabling the creation of oil tanks tailored to specific requirements. This versatility and customization potential offer design flexibility to meet industry-specific needs and optimize oil tank performance. Manufacturers can incorporate various features, such as baffles, mounting brackets, and integrated components, into the oil tanks during the moulding process, streamlining assembly and enhancing functionality.

4. Efficient Production and Cycle Time Reduction

Efficiency is a key consideration in manufacturing processes, and SMC oil tank moulds contribute to streamlined production and reduced cycle times. The moulding process allows for high-volume production of oil tanks, ensuring consistent quality and dimensional accuracy. The SMC material cures quickly, enabling fast demoulding and reducing production cycle times. This efficiency translates to increased productivity and cost savings for manufacturers, making SMC oil tank moulds a preferred choice in industries with high production demands.

5. Corrosion Resistance and Longevity

Oil tanks are subject to various corrosive substances, including oils, fuels, and chemicals. SMC oil tank moulds provide inherent resistance to corrosion, ensuring the longevity and reliability of the tanks produced. The SMC material is non-reactive to many chemicals, preventing degradation and maintaining the integrity of the oil tanks over time. The corrosion resistance of SMC oil tanks makes them suitable for a wide range of applications, including automotive fuel tanks, hydraulic fluid reservoirs, and industrial storage tanks.

Conclusion

SMC oil tank moulds have revolutionized the manufacturing process of oil tanks, delivering superior strength, durability, and efficiency. With their ability to produce lightweight yet robust tanks, these moulds offer advantages in terms of performance, fuel efficiency, and overall product quality. The versatility and customization potential of SMC oil tank moulds enable the production of tanks with complex shapes and tailored features, optimizing functionality and ease of integration. Manufacturers benefit from efficient production processes, reduced cycle times, and corrosion-resistant tanks, ensuring long-lasting performance and customer satisfaction. Embrace the precision and efficiency of SMC oil tank moulds, and elevate your oil tank production to new levels of excellence.