Benefits of LED PCBA boards

2024-07-13

A LED PCBA (Printed Circuit Board Assembly) board refers to a board that includes LEDs (Light Emitting Diodes) soldered onto a printed circuit board. Here’s an overview of LED PCBA boards and their key aspects:

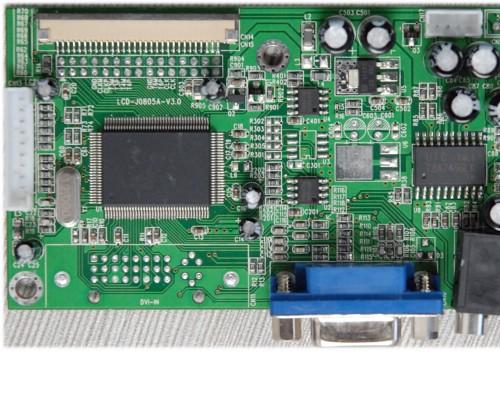

Construction and Components:

1. Printed Circuit Board (PCB):

- Substrate: Made from materials like fiberglass (FR4) or aluminum, providing a stable base for mounting electronic components.

- Copper Traces: Conductive pathways etched onto the PCB surface to connect the LEDs and other components.

2. LEDs:

- Types: Various types of LEDs can be used, including surface-mount (SMD) LEDs or through-hole LEDs, depending on the design and application requirements.

- Color and Intensity: LEDs are available in different colors (e.g., red, green, blue) and with varying brightness levels (intensity) to suit specific lighting needs.

3. Other Components:

- Resistors: Used to limit current and protect LEDs from overcurrent conditions.

- Capacitors and Inductors: Depending on the circuit design, these components may be included for filtering or energy storage purposes.

- Integrated Circuits (ICs): Controllers or drivers may be integrated to regulate LED operation and optimize performance.

Functionality:

- Light Emission: LEDs emit light when current flows through them in the forward direction, converting electrical energy into visible light.

- Control: Depending on the application, LED PCBA boards may include components for dimming, color mixing, or pattern control.

- Power Supply: Requires a stable DC power supply to operate the LEDs within their specified voltage and current ratings.

Applications:

- Lighting Products: Used in various lighting applications such as LED bulbs, strips, panels, and fixtures for residential, commercial, and industrial settings.

- Displays: Integrated into display screens, scoreboards, signage, and automotive lighting for visibility and visual impact.

- Decorative Lighting: Used in decorative lighting applications, including holiday decorations, architectural lighting, and mood lighting.

Design Considerations:

- Heat Management: LEDs generate heat, requiring proper thermal management to ensure longevity and consistent performance.

- PCB Layout: Optimize PCB layout for efficient current distribution, minimize voltage drops, and reduce electromagnetic interference (EMI).

- Environmental Conditions: Consider environmental factors such as temperature, humidity, and exposure to ensure reliability and durability of the LED PCBA board.

Benefits:

- Energy Efficiency: LEDs are highly energy-efficient compared to traditional lighting technologies, reducing power consumption and operating costs.

- Longevity: LEDs have a long operational life, typically rated for tens of thousands of hours of use, reducing maintenance and replacement frequency.

- Flexibility: LEDs offer flexibility in design, allowing for customizable lighting solutions tailored to specific requirements and aesthetics.

Maintenance:

- Inspection: Regularly inspect LED PCBA boards for signs of wear, damage, or discoloration that may indicate component failure or degradation.

- Cleaning: Keep LED surfaces clean from dust and debris to maintain optimal light output and performance.

- Repair and Replacement: Replace faulty LEDs or components as needed to ensure consistent operation and prevent potential circuit failures.

LED PCBA boards are integral components in modern lighting and display technologies, offering efficient, durable, and versatile solutions for a wide range of applications.