Parallel Comb Idler: Enhancing Conveyor Belt Performance

2025-05-21

In the world of material handling and conveyor systems, the efficiency and reliability of belt conveyors are paramount. One essential component that contributes significantly to smooth conveyor operation is the Parallel Comb Idler. This specialized idler plays a vital role in supporting and guiding conveyor belts, especially in applications requiring precise alignment and reduced material spillage.

What Is a Parallel Comb Idler?

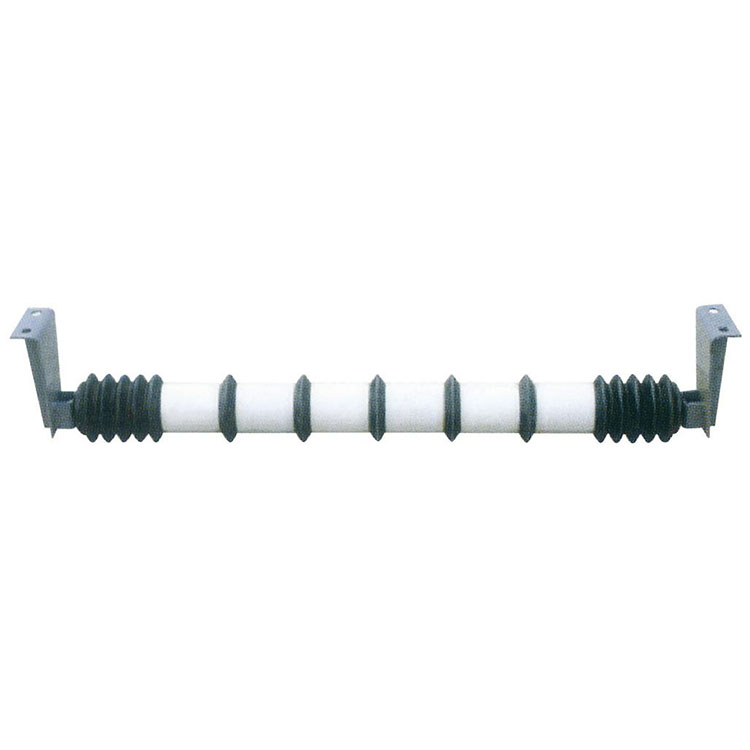

A Parallel Comb Idler is a type of conveyor idler designed with a set of parallel rollers or comb-like fingers arranged in a way that supports the conveyor belt while allowing bulk materials to pass through without clogging. Its design typically includes multiple rollers positioned side-by-side with small gaps, resembling a comb, which helps maintain belt tracking and prevent material buildup.

Key Features of Parallel Comb Idlers

Improved Belt Alignment: The parallel arrangement of rollers helps maintain the belt’s straight path, reducing misalignment and wear.

Material Spill Prevention: The comb design allows small particles to fall through the gaps, minimizing material carryback and spillage on the conveyor frame.

Durability: Built from high-quality steel or stainless steel with wear-resistant coatings, these idlers withstand harsh environments and heavy loads.

Reduced Maintenance: By minimizing belt misalignment and material accumulation, the parallel comb idler lowers downtime and maintenance costs.

Versatility: Suitable for various conveyor systems handling bulk materials such as coal, aggregates, grains, and chemicals.

Applications of Parallel Comb Idlers

Mining and Quarrying: Supporting heavy loads and abrasive materials while maintaining belt stability.

Agriculture: Handling grains and seeds with minimal contamination and spillage.

Recycling Plants: Allowing mixed materials to pass through without clogging the conveyor.

Food Processing: Ensuring smooth material flow while keeping the conveyor clean.

Manufacturing: Supporting product transport with reduced wear on belts and rollers.

Benefits of Using Parallel Comb Idlers

Enhanced Conveyor Efficiency: Proper belt tracking reduces power consumption and mechanical strain.

Increased Lifespan of Conveyor Belts: Less misalignment means less belt edge damage and longer service life.

Cleaner Operation: Reduced material buildup means cleaner work environments and easier housekeeping.

Cost Savings: Fewer stoppages and repairs translate to lower operational expenses.

Installation and Maintenance Tips

Proper Alignment: Ensure the idler is installed correctly to maximize its belt tracking capabilities.

Regular Inspection: Check for wear on rollers and replace components as needed.

Lubrication: Keep bearings well-lubricated for smooth operation and extended durability.

Cleaning: Periodically remove trapped materials to prevent blockage and wear.

Conclusion

The Parallel Comb Idler is a crucial component in conveyor belt systems, offering enhanced belt support, improved alignment, and reduced material spillage. Its specialized design benefits a wide range of industries by promoting efficient, durable, and low-maintenance conveyor operation. For businesses looking to optimize their material handling processes, investing in quality parallel comb idlers can lead to significant operational improvements and cost savings.