Sand Casting: A Timeless Manufacturing Technique for Precision and Versatility

2024-12-05

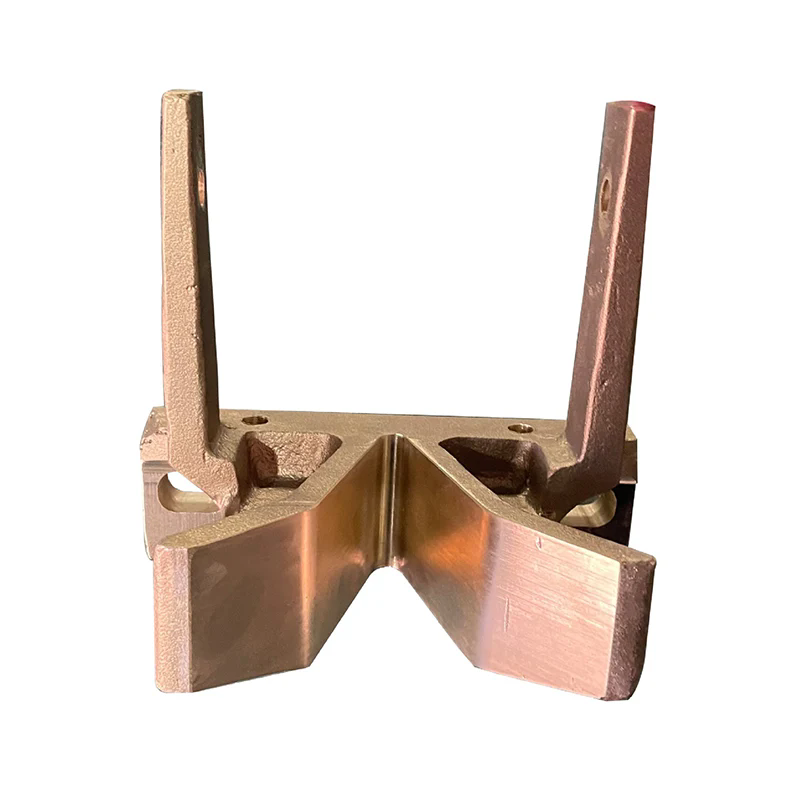

Sand casting is one of the oldest and most widely used manufacturing methods, offering unmatched versatility in producing complex metal components. This process, dating back thousands of years, continues to be a cornerstone in modern industries due to its adaptability and cost-efficiency. In this blog, we’ll explore what sand casting is, its key advantages, applications, and why it remains a critical process in today’s manufacturing landscape.

What is Sand Casting?

Sand casting is a process where molten metal is poured into a sand mold to create a desired shape. The mold is typically made by packing sand around a pattern of the object to be cast. Once the mold is ready, molten metal is introduced, allowed to cool, and then the sand is broken away to reveal the final component.

The Sand Casting Process

1. Pattern Creation

A pattern, often made of wood, metal, or plastic, is designed to mimic the shape of the desired component. This pattern is used to create the mold cavity.

2. Mold Preparation

Sand mixed with a binding agent is packed around the pattern to form the mold. The mold is then removed, leaving a hollow cavity.

3. Melting and Pouring

The chosen metal is melted in a furnace and carefully poured into the mold cavity.

4. Cooling and Solidification

The metal is allowed to cool and harden inside the mold, taking on the shape of the cavity.

5. Breaking the Mold

The sand mold is broken away, revealing the cast component.

6. Finishing

The component is cleaned, trimmed, and machined as needed to meet specifications.

Advantages of Sand Casting

1. Cost-Effective

Sand casting is economical, especially for small production runs, as the materials are inexpensive and reusable.

2. Design Flexibility

This process can produce highly complex shapes and large-sized components that might be challenging or impossible with other methods.

3. Wide Material Compatibility

Sand casting can accommodate various metals, including aluminum, iron, steel, and bronze.

4. Low Lead Times

The simplicity of the process allows for faster production, making it ideal for prototyping and custom orders.

5. Scalability

Sand casting is suitable for both small-scale production and large-volume manufacturing.

Applications of Sand Casting

1. Automotive Industry

Sand casting is used to produce engine blocks, cylinder heads, and transmission components.

2. Aerospace

The process is applied to create complex parts like turbine blades and structural components.

3. Construction

Structural metal parts, brackets, and fittings are commonly made through sand casting.

4. Machinery and Equipment

Many industrial machine parts and tools are created using this method due to its ability to handle large and heavy components.

5. Art and Sculptures

Sand casting is also favored for creating intricate decorative pieces and custom art installations.

Why Sand Casting Endures in Modern Manufacturing

Despite advancements in manufacturing technologies, sand casting remains relevant due to its unique ability to produce complex and large-scale parts cost-effectively. The process adapts well to customizations, making it indispensable for specialized industries. Furthermore, ongoing innovations in sand and binder materials continue to improve the efficiency and precision of sand casting, ensuring its place in the future of manufacturing.

Conclusion

Sand casting is a timeless manufacturing technique that combines simplicity with versatility. Its ability to create complex components from various metals makes it a valuable process across industries. Whether for large-scale industrial applications or artistic endeavors, sand casting demonstrates that traditional methods can stand the test of time when they meet the demands of modern production.