Suspension Tester: Ensuring Vehicle Stability and Safety

2024-12-05

The suspension system is a critical component of any vehicle, ensuring a smooth ride, maintaining control, and enhancing safety. A suspension tester is an essential tool for evaluating the performance of a vehicle's suspension system. By diagnosing issues and ensuring components are functioning optimally, this equipment plays a pivotal role in automotive maintenance and safety checks.

What is a Suspension Tester?

A suspension tester is a diagnostic device designed to measure and evaluate the efficiency of a vehicle's suspension system. It tests various elements such as damping performance, wheel alignment, and vibration levels, providing insights into how well the suspension absorbs shocks and maintains contact with the road.

How Does a Suspension Tester Work?

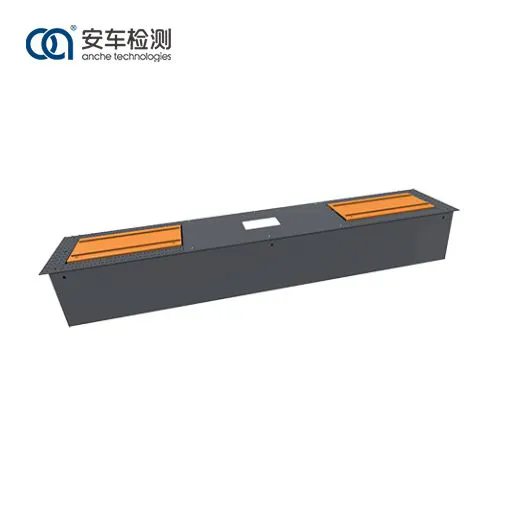

Suspension testers typically operate by placing the vehicle's wheels on vibrating platforms. These platforms simulate road conditions, allowing the tester to measure the reaction of the suspension system. Sensors and software then analyze the data, determining the effectiveness of the shock absorbers, springs, and other suspension components.

Key Features of a Suspension Tester

1. Dynamic Testing

Simulates real-world driving conditions to provide accurate performance data.

2. Digital Analysis

Advanced models use sensors and software for precise measurements and detailed reporting.

3. Compatibility

Suspension testers are versatile, accommodating a range of vehicles from small cars to heavy-duty trucks.

4. Safety Checks

Identifies potential suspension failures that could compromise vehicle stability.

5. Efficiency

Offers quick and reliable results, making it ideal for workshops and inspection stations.

Benefits of Using a Suspension Tester

1. Improved Safety

Regular testing ensures that the suspension system performs correctly, reducing the risk of accidents caused by poor road grip or instability.

2. Enhanced Ride Comfort

A well-maintained suspension system absorbs shocks effectively, resulting in a smoother driving experience.

3. Early Problem Detection

Suspension testers help identify issues early, preventing costly repairs and extending the lifespan of the suspension system.

4. Compliance with Regulations

In many regions, suspension testing is part of mandatory vehicle inspections to meet safety standards.

5. Accurate Diagnostics

Advanced testers provide detailed insights, helping mechanics make informed decisions during repairs.

Applications of Suspension Testers

1. Automotive Workshops

Mechanics use suspension testers to diagnose and repair suspension-related problems.

2. Inspection Stations

Mandatory safety checks often include suspension testing to ensure vehicles meet legal standards.

3. Manufacturing Quality Control

Automakers use suspension testers to evaluate and improve suspension systems in new vehicles.

4. Fleet Management

Transportation companies rely on suspension testing to maintain vehicle reliability and safety.

Why Suspension Testing Matters

The suspension system doesn’t just contribute to comfort; it’s integral to vehicle control, braking efficiency, and road safety. A compromised suspension can lead to uneven tire wear, reduced stability, and increased braking distances. Regular testing ensures optimal performance and prevents potential hazards.

Choosing the Right Suspension Tester

When selecting a suspension tester, consider factors such as testing capacity, accuracy, compatibility with different vehicle types, and ease of operation. High-quality models offer digital interfaces and comprehensive reporting, making them ideal for professional use.

Conclusion

A suspension tester is a vital tool for maintaining vehicle performance and safety. By providing accurate diagnostics and ensuring compliance with safety standards, it benefits mechanics, manufacturers, and drivers alike. Investing in regular suspension testing not only enhances driving comfort but also ensures peace of mind on the road.