What Is a Brake Tester and Why Is It Critical for Vehicle Safety?

2025-07-16

A Brake Tester is a diagnostic device used to measure the performance and effectiveness of a vehicle’s braking system. It plays a crucial role in ensuring that vehicles meet safety standards and can stop effectively under various conditions. Brake testers are commonly used in vehicle inspection centers, workshops, manufacturing plants, and testing facilities.

How Does a Brake Tester Work?

There are several types of brake testers, but the most common is the roller brake tester, especially used for cars, trucks, and buses. Here's how it typically works:

1. Vehicle Positioned on Rollers: The vehicle is driven onto the brake tester, and the wheels rest on a set of powered rollers.

2. Roller Rotation: The rollers rotate the wheels while the brakes are applied.

3. Force Measurement: Sensors measure the braking force applied by each wheel.

4. Results Displayed: The machine shows data such as brake force, imbalance, efficiency, and deceleration rate.

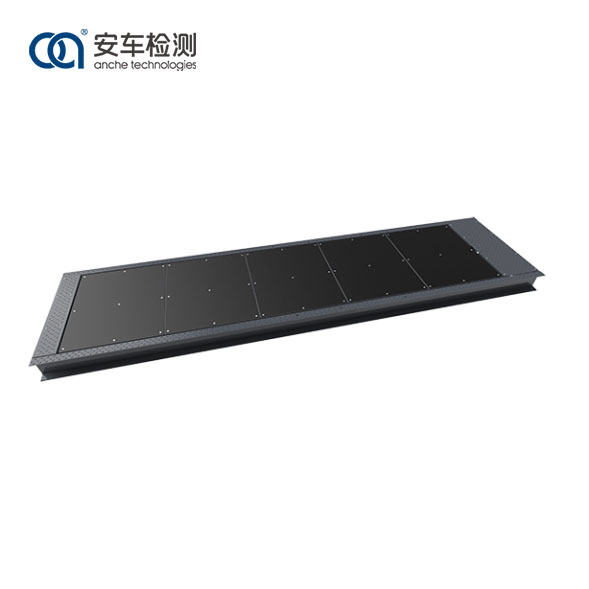

Other types include plate brake testers, which measure braking force as the vehicle passes over sensor plates, and decelerometers, which are portable and measure the deceleration when the brakes are applied during a road test.

Why Are Brake Testers Important?

Ensure Road Safety: They help detect brake system faults that could lead to accidents.

Compliance with Regulations: Many countries require periodic brake testing as part of roadworthiness inspections.

Accurate Diagnosis: Mechanics can pinpoint issues like uneven braking, worn brake pads, or hydraulic imbalances.

Preventative Maintenance: Early detection of brake wear or malfunction can save costs and prevent failures.

Key Features of a Brake Tester

High Accuracy Sensors: For reliable readings on brake force and imbalance.

Digital Display and Reporting: Many models include software for printing test reports.

Axle Load Compensation: Adjusts results based on vehicle weight.

Wireless or Remote Operation: In modern systems for convenience and efficiency.

Heavy-Duty Versions: Suitable for trucks, buses, and trailers.

Where Are Brake Testers Used?

Vehicle Inspection Stations

Automotive Repair Shops

Fleet Maintenance Garages

Vehicle Manufacturing Plants

Government Road Safety Programs

Choosing the Right Brake Tester

When selecting a brake tester, consider:

Vehicle Type: Light vehicles vs. heavy-duty vehicles.

Test Capacity: Maximum axle weight and wheelbase.

Installation Type: In-ground or portable.

Compliance Standards: Ensure the tester meets local or international testing standards.

Ease of Use: User interface, automation level, and software compatibility.

Conclusion

A brake tester is a vital tool for maintaining vehicle safety and reliability. Whether you're running a service center or a transport fleet, having a reliable brake testing system ensures that every vehicle on the road can stop safely and effectively. Regular brake performance checks are not only a legal requirement in many regions but also a smart investment in road safety.