What Makes Alumina Ceramic a Top Choice in Advanced Engineering?

2025-06-25

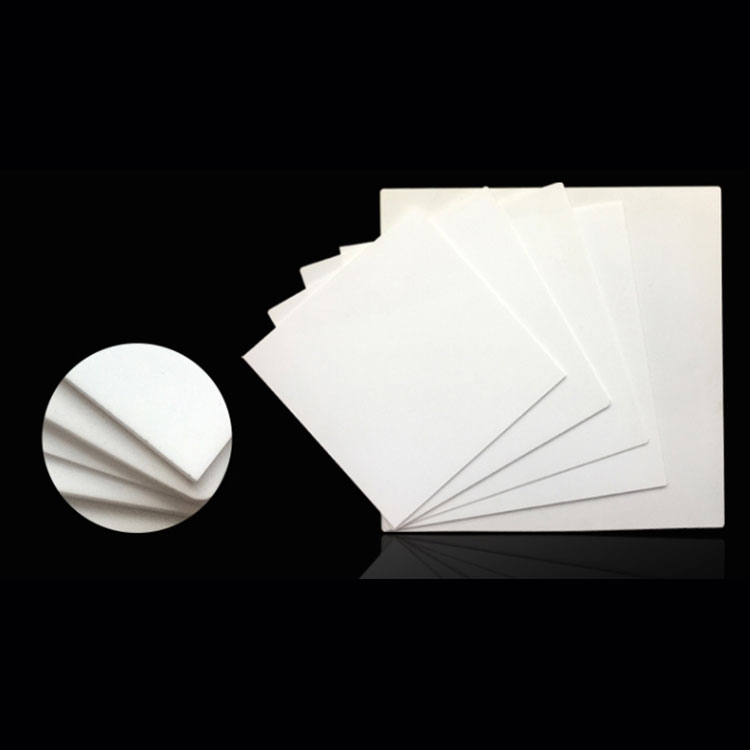

In the world of advanced materials, Alumina Ceramic—also known as aluminum oxide —stands out for its exceptional strength, durability, and versatility. From electronics to industrial machinery, this high-performance ceramic is widely used across numerous industries. But what exactly makes alumina ceramic so valuable?

What Is Alumina Ceramic?

Alumina ceramic is a non-metallic, inorganic material made from aluminum oxide, a compound known for its hardness and thermal resistance. It is one of the most widely used technical ceramics due to its excellent combination of mechanical strength, electrical insulation, and resistance to wear and corrosion.

What Are the Key Properties?

Alumina ceramics are favored for a number of outstanding characteristics, including:

High hardness: Nearly as hard as sapphire, making it extremely resistant to scratching and wear.

Excellent thermal stability: Can withstand temperatures above 1600°C.

Electrical insulation: Ideal for use in electrical insulators and components.

Corrosion resistance: Performs well in harsh chemical environments.

Biocompatibility: Safe for medical and dental applications.

These properties make alumina ceramic ideal for demanding environments where traditional materials might fail.

Where Is It Used?

Thanks to its unique qualities, alumina ceramic plays a crucial role in many industries:

Electronics: Used in substrates, insulators, and semiconductor parts.

Automotive: Found in engine components, seals, and sensors.

Medical: Used in dental implants, prosthetics, and surgical tools.

Mechanical and chemical processing: Ideal for pump seals, bearings, nozzles, and valves.

Aerospace and defense: Applied in armor, heat shields, and protective casings.

Its reliability and performance under stress make it a go-to material in critical applications.

Why Choose Alumina Ceramic?

Choosing alumina ceramic is about ensuring long-term performance, safety, and efficiency. Whether you're designing a high-precision electronic device or developing equipment for corrosive environments, alumina ceramic provides a dependable solution. It offers:

Extended service life

Minimal maintenance

Resistance to high-impact stress

While it may come at a higher initial cost compared to plastics or metals, its durability often reduces total lifecycle costs.

Final Thoughts

Alumina ceramic continues to be a cornerstone of modern engineering materials. Its balance of strength, heat resistance, and electrical insulation make it indispensable in today's high-tech industries. As technology evolves, so too does the demand for reliable materials—and alumina ceramic remains at the forefront.