Why Is a PVC Air Knife Essential for Industrial Applications?

2024-12-26

In industrial environments, efficiency and precision are critical, and achieving optimal airflow for tasks like cleaning, drying, cooling, or drying can make a significant difference. This is where the PVC air knife comes in. But why is a PVC air knife essential for industrial applications? Let’s explore the advantages of this tool and why it’s becoming increasingly popular across various industries.

1. What Is a PVC Air Knife?

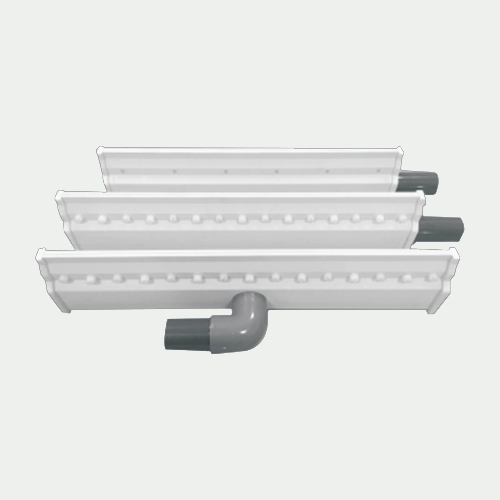

A PVC air knife is an air delivery system designed to produce a high-velocity, even sheet of airflow. Made from durable PVC material, the air knife utilizes compressed air to generate a controlled flow of air across a surface. This makes it ideal for a wide variety of industrial processes that require efficient removal of debris, moisture, or heat. The design allows for a uniform airflow, minimizing the air loss typically seen in traditional nozzles or blow guns.

2. Why Choose PVC for Air Knives?

PVC (Polyvinyl Chloride) is often the material of choice for air knives due to its unique set of properties:

- Durability: PVC is highly resistant to chemicals, corrosion, and wear, making it perfect for harsh industrial environments.

- Lightweight: Despite its durability, PVC is a relatively lightweight material, which makes PVC air knives easy to handle and install.

- Cost-Effective: PVC is a cost-efficient material, offering a good balance between performance and affordability in industrial applications.

- Non-conductive: PVC’s non-conductive nature makes it a safer option when working around electrical equipment or sensitive materials.

3. How Do PVC Air Knives Improve Efficiency in Industrial Processes?

PVC air knives provide significant improvements in efficiency, especially when compared to traditional methods like air nozzles or brushes. Here’s how:

- Uniform Airflow: PVC air knives deliver a consistent sheet of air, ensuring that the surface being treated (whether for cleaning or drying) is covered evenly. This leads to better results in less time.

- Reduced Air Consumption: Unlike blow guns, which are inefficient and waste air, air knives direct the airflow across the entire surface, maximizing the use of compressed air and reducing energy costs.

- Faster Drying and Cooling: With their high-velocity airflow, PVC air knives are excellent for drying or cooling large areas or products quickly. This is essential in industries like food processing, automotive manufacturing, and printing.

- Minimized Damage to Surfaces: Because the air is spread out evenly, PVC air knives reduce the risk of damage to delicate surfaces compared to more focused, high-pressure nozzles.

4. What Industries Benefit Most from PVC Air Knives?

PVC air knives are versatile and can be used in numerous industries. Here are just a few where they are especially beneficial:

- Manufacturing: In manufacturing environments, PVC air knives can be used for cleaning parts, removing debris, or cooling products during production.

- Food Processing: Air knives are used to dry or cool food products quickly while maintaining hygiene standards.

- Printing: PVC air knives are often employed in printing to quickly dry ink on paper, ensuring that prints dry faster and reduce the risk of smudging.

- Automotive: In the automotive industry, air knives help remove excess fluids, clean parts, or dry off coatings before the next step in assembly or painting.

5. How Can PVC Air Knives Be Customized for Specific Applications?

One of the significant advantages of PVC air knives is that they can be customized to suit a wide variety of industrial tasks. Some common customizations include:

- Size and Length: PVC air knives can be made in various sizes to cover small to large surfaces, depending on the needs of the application.

- Airflow Adjustments: Many air knives offer adjustable airflow controls, allowing operators to fine-tune the pressure and volume of air for optimal performance.

- Shape Modifications: Some air knives can be customized to target specific areas or angles, such as for drying complex shapes or parts that require precision cleaning.

- Nozzle Options: The nozzle design can be tailored to direct airflow where it's needed most, whether that’s a broad, gentle flow or a focused, high-velocity stream.

6. How Are PVC Air Knives Maintained?

Proper maintenance of PVC air knives ensures they continue to perform at their best. Some simple maintenance tips include:

- Regular Inspection: Check the air knife for wear and tear or any buildup of debris that could obstruct the airflow. Cleaning the unit regularly will help maintain optimal performance.

- Air Supply Check: Make sure the air supply is clean and properly filtered, as contaminants can affect the air knife’s effectiveness and longevity.

- Tighten Connections: Ensure all connections are secure and tight to avoid leaks or air loss, which can reduce efficiency.

- Check for Cracks: Although PVC is durable, it’s important to check for cracks or damage that may occur due to harsh use or exposure to extreme temperatures.

7. What Are the Advantages of Using a PVC Air Knife Over Other Air Delivery Systems?

While there are several air delivery systems available in the market, PVC air knives stand out due to the following advantages:

- Higher Efficiency: PVC air knives consume less compressed air while delivering greater air coverage, resulting in reduced operational costs.

- Environmental Benefits: By utilizing less air and energy, PVC air knives are more eco-friendly compared to other air tools.

- Versatility: Whether you need to blow off debris, dry products, or cool surfaces, PVC air knives offer a broad range of applications in a variety of industries.

- Easy Installation and Use: PVC air knives are easy to set up and can be used in both manual and automated systems, making them adaptable to different environments.

Final Thoughts

In the world of industrial equipment, PVC air knives stand out as essential tools for improving efficiency, reducing energy costs, and maintaining high-quality standards in operations. Their versatility, durability, and ease of use make them a valuable asset for industries ranging from automotive to food processing.