Why Is Steel Wire Rope the Backbone of Heavy-Duty Applications?

2024-12-12

When it comes to applications that require strength, durability, and reliability, few materials stand up to the task quite like steel wire rope. Used in industries ranging from construction to transportation and marine operations, steel wire rope plays a crucial role in ensuring the safe and efficient handling of heavy loads. But why is steel wire rope considered the backbone of so many heavy-duty applications? Let’s dive into the reasons behind its widespread use.

What Is Steel Wire Rope?

Steel wire rope is a type of rope made from multiple strands of steel wires that are twisted together to form a single strong, flexible unit. These ropes are designed to withstand substantial tensile forces and are commonly used in lifting, towing, and securing heavy equipment. The construction of steel wire rope allows it to offer a combination of strength, flexibility, and resistance to wear that is unmatched by other materials.

Unmatched Strength and Durability

The primary reason steel wire rope is so widely used is its incredible strength. Made from high-carbon steel, these ropes can handle significant loads without breaking or snapping, which is why they are often used in cranes, elevators, and heavy machinery. Steel wire ropes are built to withstand high tension, making them ideal for lifting, pulling, and securing extremely heavy loads over long distances.

In addition to their strength, steel wire ropes are incredibly durable. They can endure harsh environmental conditions, including exposure to moisture, UV rays, and extreme temperatures, without losing their structural integrity. This makes them perfect for outdoor and industrial environments where reliability is key.

Flexibility and Versatility

One of the standout features of steel wire rope is its flexibility. Despite being made of steel, the rope is designed to bend and twist without losing its strength or breaking. This flexibility makes it suitable for a wide range of applications, from winding around pulleys and sheaves to navigating through complex machinery. Whether in cranes, hoists, or winches, steel wire ropes can adapt to the specific demands of various systems.

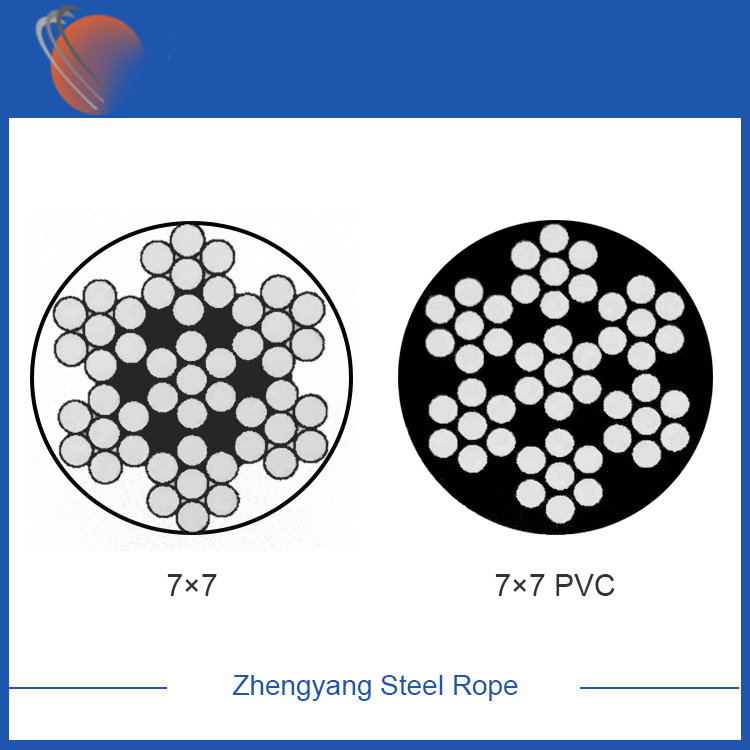

Moreover, steel wire ropes are highly versatile. They come in various constructions, from single-strand to multi-strand, and can be customized in terms of thickness, strength, and coating to suit specific applications. Whether you're working in a mining operation, an offshore drilling rig, or a construction site, there's a steel wire rope configuration to meet your needs.

Resistance to Abrasion and Wear

Another reason steel wire rope is preferred in demanding applications is its resistance to abrasion. As steel wire ropes are constantly exposed to friction, dirt, and harsh conditions, they are designed to resist wear and tear. Many steel wire ropes are coated with materials like zinc (galvanized steel) to protect against rust and corrosion, further extending their lifespan and maintaining performance under tough conditions.

This makes steel wire rope particularly suitable for industries like mining and shipping, where ropes are frequently in contact with rough surfaces and subjected to continuous use. With the right maintenance and regular inspections, steel wire ropes can last for many years, even in the harshest environments.

Safety and Reliability in Critical Operations

In many applications, steel wire rope is not just a matter of convenience—it’s a matter of safety. Whether used in lifting equipment, suspension bridges, or rescue operations, the integrity of the wire rope is critical to the success of the operation. Steel wire ropes are engineered with a high safety factor, meaning they are designed to handle loads much greater than what they will typically encounter, providing an extra level of reliability and peace of mind.

The rope’s ability to stretch under load without breaking, while maintaining a high tensile strength, adds a layer of safety that other materials may lack. Additionally, periodic inspections and maintenance can help identify wear or fatigue before it becomes a serious issue, ensuring the rope continues to perform safely.

Applications Across Multiple Industries

Steel wire rope’s unique combination of strength, flexibility, and durability makes it indispensable in various industries. Some of the most common applications include:

- Construction: Cranes and hoists rely on steel wire rope to lift and lower heavy materials and equipment.

- Marine: Steel wire ropes are used in shipping and offshore operations for towing, anchoring, and securing ships.

- Mining: Steel wire ropes are essential for lifts, hoists, and cableways, allowing for the transport of people and materials in mines.

- Transportation: Suspension bridges, cable cars, and ski lifts all rely on steel wire rope for their strength and safety.

- Oil and Gas: Offshore rigs and drilling platforms use steel wire ropes to handle heavy equipment and machinery in harsh conditions.

Why Choose Steel Wire Rope for Heavy-Duty Tasks?

The versatility and strength of steel wire rope make it an excellent choice for heavy-duty tasks. It offers the combination of flexibility, resistance to wear, and tensile strength required to handle the most demanding applications. Whether you need to lift heavy loads, secure equipment, or operate machinery, steel wire rope is a reliable, long-lasting solution.

In conclusion, steel wire rope remains the backbone of heavy-duty operations due to its unmatched strength, flexibility, durability, and versatility. It is a trusted material that plays a vital role in industries ranging from construction to marine and mining. If you’re looking for a reliable and efficient solution to handle heavy loads and harsh conditions, steel wire rope should be your go-to choice.